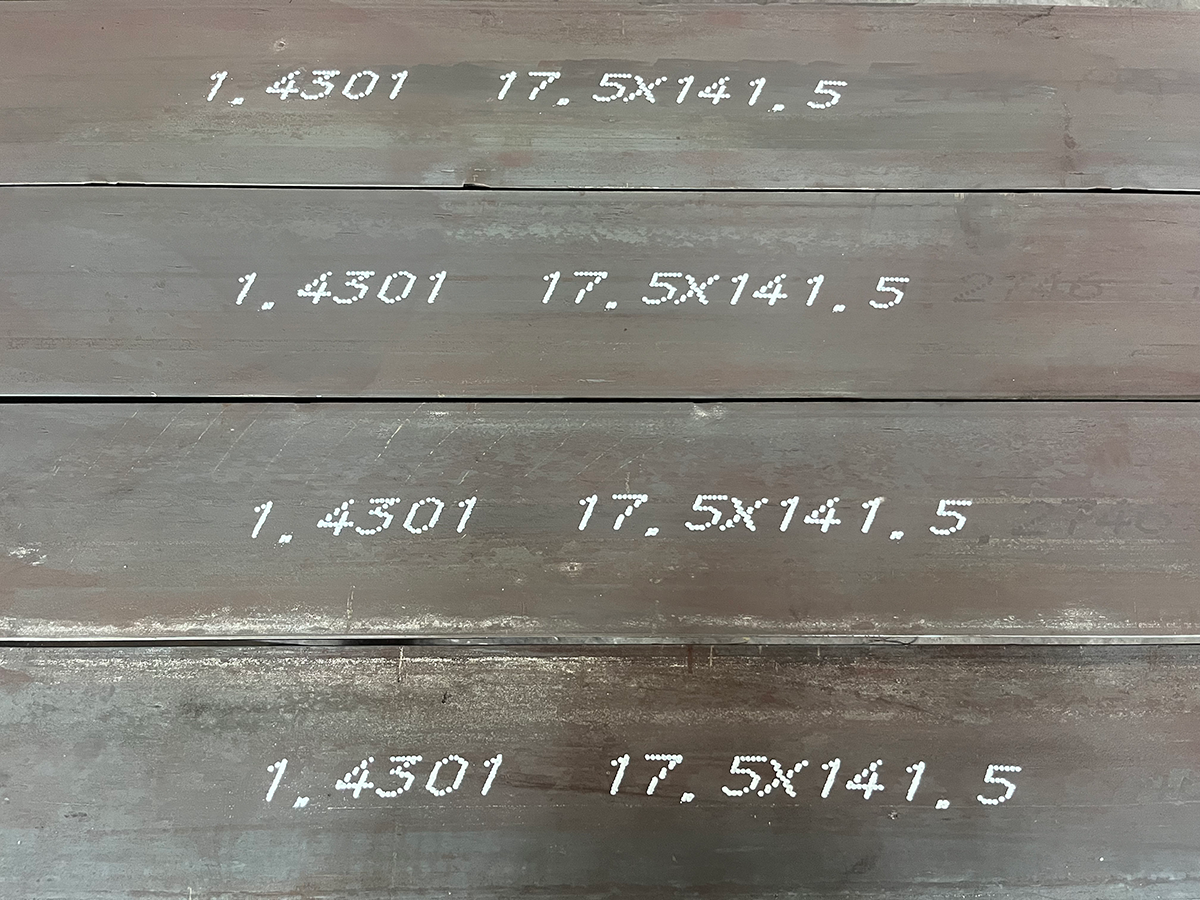

4301 Steel

Designation by Standards

Brand Name | Ravne | Mat. No. | DIN | EN | AISI/SAE |

SINOXX 4301 | PK11EX | 1.4301* | - | X5CrNi18-10 | 304 |

Chemical Composition (in weight %)

C | Si | Mn | Cr | Mo | Ni | V | W | Others |

max. 0.07 | max. 1.00 | max. 2.00 | 18.25 | - | 9.25 | - | - | - |

Description

One of the most widely used and oldest of the stainless steels. This was originally called 18-8 which stood for its chromium and nickel content. It possesses an excellent combination of strength, corrosion resistance and fabricability.

The list is endless. Almost every conceivable industry uses some of this material in some way. Everything from stovetops to ball point pen barrels to flatware to fasteners has been fabricated from this alloy.

Physical properties (average values) at ambient temperature Modulus of elasticity [103 x N/mm2]: 200, 186 (200oC), 172(400oC) Density [g/cm3]: 7.92

Thermal conductivity [W/m.K]: 15.0

Electric resistivity [Ohm mm2/m]: 0.73 Specific heat capacity[J/g.K]: 0.50

20-100oC | 20-200oC | 20-300oC | 20-400oC | 20-500oC |

16.0 | 17.0 | 17.0 | 18.0 | 18.0 |

Hardening

Harden from a temperature of 1000-1080oC followed by water or air (sufficiently fast) quenching. Structure after quenching is austnite withn small ferrite component.

0.2 % proof stress: 190 N/mm2 (for d<=160, 160<d<=250)

1.0 % proof stress: 190 N/mm2 (for d<=160, 160<d<=250) Tensile strength: 225 N/mm2( for d<=160, 160<d<=250)

Elongation: 45% (for d<=160, longit.), 35% (for 160<d<=250, transv.)

Notch impact energy (ISO-V): 100 J (for d<=160, longit.), 60 J (for 160<d<=250, transv.) Resistance to interystalline corrosion: yes (in as delivered condition), no (in sensitised condition)

Note: Sensitisation treatment for 15 min at 700oC with subsequent cooling in air.

Temperature | 100oC | 150oC | 200oC | 250oC | 300oC | 350 oC | 400 oC | 450o C | 500 oC | 550o C |

0.2 % proof stress in N/mm2 | 155 | 140 | 127 | 118 | 110 | 104 | 98 | 95 | 92 | 90 |

1.0 % proof stress in N/mm2 | 190 | 170 | 155 | 145 | 135 | 129 | 125 | 122 | 120 | 120 |

Forging

Hot forming temperature: 1200-900oC.

Slow speeds and heavy feeds will minimize this alloys tendency to work harden. Due to long stringy chips, the use of chip breakers is advisable. Many companies now offer premium machinability grades, such as CarTech with their Project 70 and 7000 series.

Resistant to a wide range of environments between moderately reducing and slightly oxidizing. This covers food, fresh water, sterilizing solutions and dilute nitric and acetic acids.

All fusion and resistance processes have been successfully employed in welding 304. AWS E/ER308 or 312 filler metal is recommended.

Readily fabricated by most cold working methods, 304 may require intermediate annealing to avoid cracking or tearing from radical deformation. Full annealing should follow any operation to reduce internal stress and optimize corrosion resistance.

Forms manufactured: Please see the Dimensional Sales Program.

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Unless otherwise specified, registered trademarks are property of SIJ Metal Ravne company. Copyright 2016 by SIJ Metal Ravne d.o.o. All rights reserved. Contact our Sales Office for more information.