SINOXX 4021 Steel

Designation by Standards

Brand Name | Ravne | Mat. No. | DIN | EN | AISI/SAE |

SINOXX 4021 | PK3 | 1.4021 | X20Cr13 | X20Cr13 | 420 |

Chemical Composition (in weight %)

C | Si | Mn | Cr | Mo | Ni | V | W | Others |

0.20 | max. 1.0 | max. 1.50 | 13.0 | - | - | - | - | - |

Description

This alloy is a general purpose heat treatable chromium steel which is a popular cutlery grade. Martensitic stainless steel.

Applications

Dental and surgical instruments, cutlery, pump shafts, plastic molds and dies, steel balls, and various hand tools, pump components, shafts, turbine blades, pressing dies for tablets, glass and plastics processing tools.

Physical properties (average values) at ambient temperature

Modulus of elasticity [103 x N/mm2]: 216 Density [g/cm3]: 7.73

Thermal conductivity [W/m.K]: 30.0

Electric resistivity [Ohm mm2/m]: 0.60 Specific heat capacity[J/g.K]: 0.46

Coefficient of Linear Thermal Expansion 10-6 oC-1

20-100oC | 20-200oC | 20-300oC | 20-400oC | 20-500oC |

10.5 | 11.0 | 11.5 | 12.0 | 12.0 |

Modulus of Elasticity [103 N/mm2]

20oC | 200oC | 400oC |

216 | 205 | 190 |

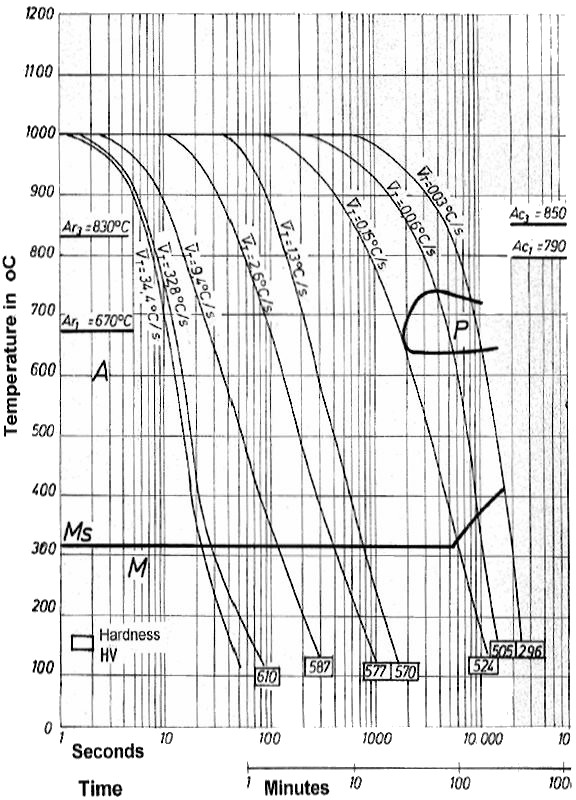

Continuous Cooling Transformation (CCT) Diagram

Soft Annealing

Heat to 730-810oC, air cooling. Structure is ferrite with spherical carbides.

Hardening

Harden from a temperature of 950-1050oC followed by oil, air quenching.

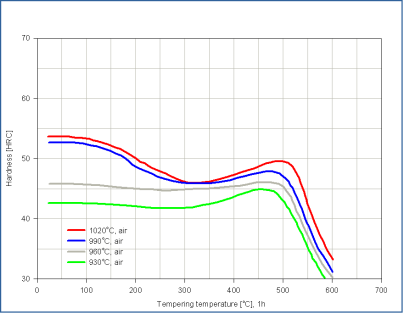

Tempering

Tempering temperature: 650-750oC. Transformation structure with ferrite.

Mechanical Properties at Room Temperature

Size range mm |

Heat treatment condition |

0.2 % proof stress (N/mm2) | Tensile strengt h (N/mm 2) |

Elongation (%) | Notch impac t energ y (ISO- V) (J) |

Hardness HB max. |

d<=160 | Q+T 700 | 500 | 700- 850 | 13 | 25 | 230 |

d<=160 | Q+T 800 | 600 | 800- 950 | 12 | 20 | 230 |

0.2 % Proof Stress (N/mm2) at Elevated Temperatures

Conditi on | 100oC | 150oC | 200oC | 250oC | 300oC | 350oC | 400oC |

Q+T 700 | 460 | 445 | 430 | 415 | 395 | 365 | 330 |

Q+T 800 | 515 | 495 | 475 | 460 | 440 | 405 | 355 |

Diagram Tempering Temperature - Mechanical Properties

Forging

Hot forming temperature: 1100-850oC.

Machinability

Similar to machining some of the high carbon tool steel, this alloy has tough, stringy chip build-up.

Embittlemnt: It must be in mind that the temperature range between 425 and 525oC must be avoided owing to embritllement at 475oC.

Corrosion Resistance

420 is resistant to the atmosphere, fresh water, dilute acids and alkalis and fruit and vegetable juices.

Welding

Not commonly welded due to its air hardening characteristics. Welding may be performed after preheating to 149-204oC with post weld tempering at temperature for 2 hours. Filler metal should be AWS E/ER420.

Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Unless otherwise specified, registered trademarks are property of SIJ Metal Ravne company. Copyright 2016 by SIJ Metal Ravne d.o.o. All rights reserved. Contact our Sales Office for more information.