SIMOLD 2085 Steel

Designation by Standards

Brand Name | Ravne | Mat. No. | DIN | EN | AISI/SAE |

SIMOLD 2085 | PK4S | 1.2085 | X33CrS16 | - | - |

Chemical Composition (in weight %)

C | Si | Mn | Cr | Mo | Ni | V | W | Others |

0.30 | max. 1.00 | max. 1.40 | 15.00-17.00 | - | max. 1.00 | - | - | - |

Description

Martensitic stainless steel resistant to corrosion. Steel PK4S displays the best corrosion resistance in hardened condition with a surface polished to give a mirror finisih. Properties: Magnetizable steelm good mechanical resistance and toughness, excellent for manufacturing of components that have to resist to aggressive plastics, good tool machinability thanks to its sulphur content, suitable for working in wet atmosphere and moisture, suitable for polishing, wear and corrosion proof, and very stable dimensionally during heat treatment.

All kinds of cutting tools - dies and die-blocks in the plastics industry such as PVC, knives, shears, surgical instruments, moulds for plastics production, as well as for surgical instruments and measuring gauges.

Modulus of elasticity [103 x N/mm2]: 212 Density [g/cm3]: 7.65

Thermal conductivity [W/m.K]: 18

Electric resistivity [Ohm mm2/m]: 0.65 Specific heat capacity[J/g.K]: 460 Magnetisable: Yes

20-100oC | 20-200oC | 20-300oC | 20-400oC | 20-500oC |

11.0 | 11.1 | 11.2 | 11.8 | 12.0 |

Soft Annealing

Heat to 760-780oC, cool slowly. This will produce a maximum Brinell hardness of 230.

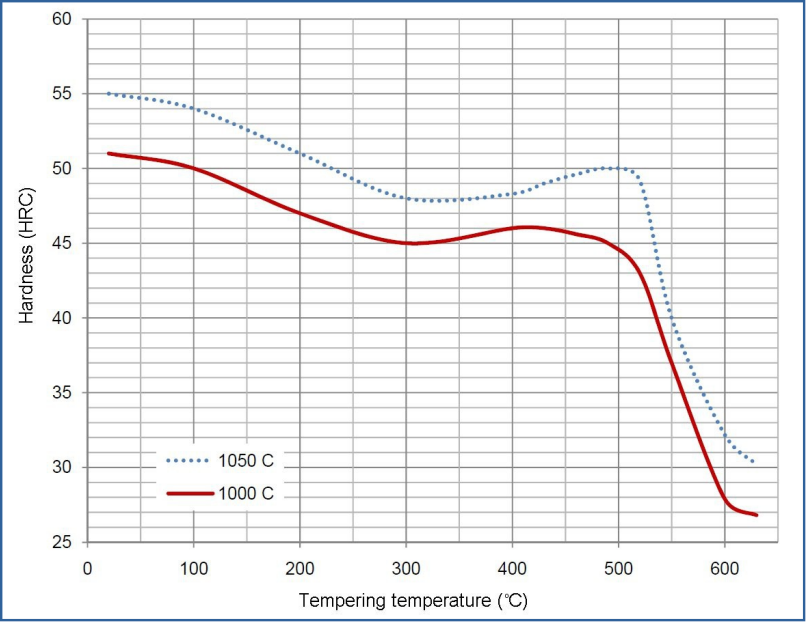

Preheating: 800oC. Harden from a temperature of 1000-1050oC followed by oil, or polymer cooling bath. Hardness after quenching is 51-55 HRC.

Tempering temperature: 150-200oC. See the tempering diagam.

Forging

Hot forming temperature: 1050-850oC, slow cooling.

Very good machinability.

Forms manufactured: Please see the Dimensional Sales Program.

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Unless otherwise specified, registered trademarks are property of SIJ Metal Ravne company. Copyright 2016 by SIJ Metal Ravne d.o.o. All rights reserved. Contact our Sales Office for more information.