2738 Steel

Designation by Standards

Brand Name | Ravne | Mat. No. | DIN | EN | AISI/SAE |

SIMOLD 2738 | UTOPNIN | 1.2738 | 40CrMnNiMo8-6-4 | - | P20 Mod. |

Chemical Composition (in weight %)

C | Si | Mn | Cr | Mo | Ni | V | W | Others |

0.40 | 0.30 | 1.45 | 1.95 | 0.20 | 1.05 | - | - | - |

Description

This steel is in the category generally labeled as Mold Steels. Nickel and chromium are the alloying elements for hardness and toughness. Cold work tool steel with good machinability, excellent polishability, suitable for texturing. Improved through hardenability comapred to Mat.No. 1.2311.

Applications

Typically used for relatively low temperature applications such as die casting dies and injection molds, synthetic plastic moulds dies, for large moulds.

Physical properties (average values) at ambient temperature

Modulus of elasticity [103 x N/mm2]: 205 Density [g/cm3]: 7.80

Thermal conductivity [W/m.K]: 29.0

Specific heat capacity[J/g.K]: 0.46

Coefficient of Linear Thermal Expansion 10-6 oC-1

20-100oC | 20-200oC | 20-300oC | 20-400oC | 20-500oC | 20-600oC | 20-700oC |

11.7 | 12.3 | 13.0 | 13.3 | 13.7 | 13.7 | 14.0 |

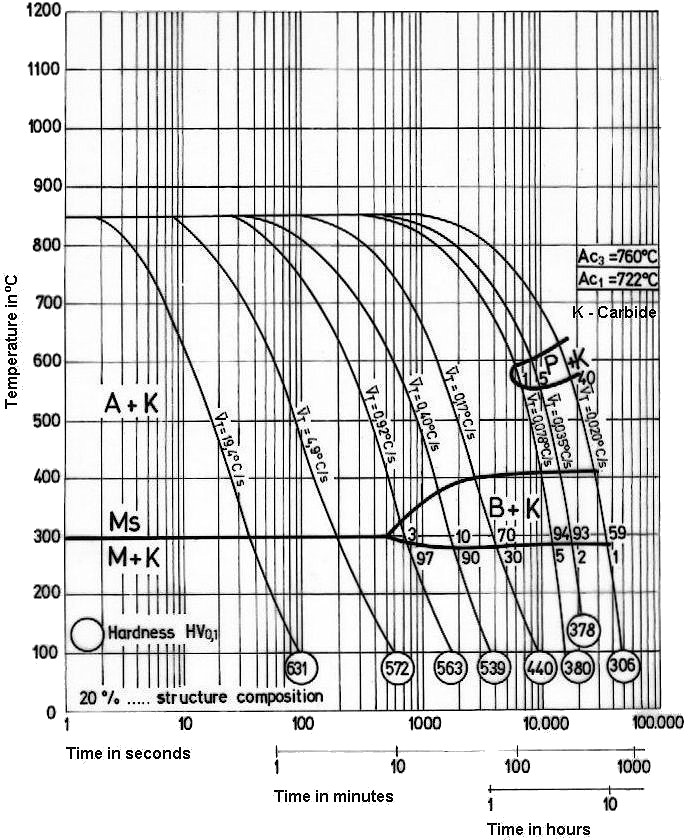

Continuous Cooling Transformation (CCT) Diagram

Soft Annealing

Heat to 710-740oC, cool slowly. This will produce a maximum Brinell hardness of 235.

Stress Relieving

Stress relieving to remove machining stresses should be carried out by heating to 650oC, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening

Harden from a temperature of 840-880oC followed by oil, air ot warm bath (180-220oC) quenching. Hardness after quenching is 52 HRC.

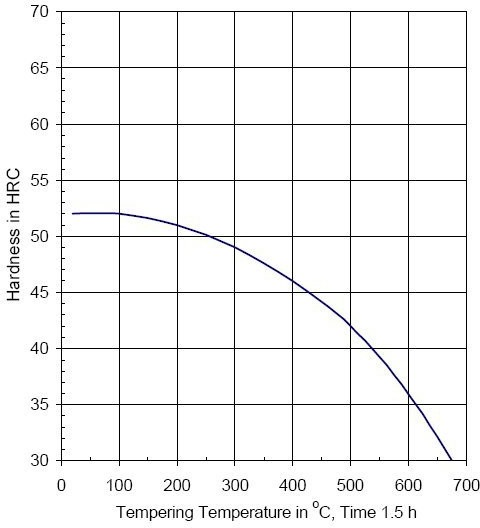

Tempering

Tempering temperature: See the data bellow.

Tempering Temperature (oC) vs. Hardness (HRC) vs. Tensile Stregth (N/mm2)

100oC | 200oC | 300oC | 400oC | 500oC | 600oC | 700oC |

52 | 51 | 49 | 46 | 42 | 36 | 28 |

1790 | 1730 | 1620 | 1480 | 1330 | 1140 | 920 |

Tempering Diagram

Forging

Hot forming temperature: 1093-898oC.

Machinability

Machinability is relatively good at about 80% that of the W group water hardening steels.

Welding

This alloy is weldable by conventional methods. Contact the alloy supplier for details and weld procedures. Forms manufactured: Please see the Dimensional Sales Program.

Disclaimer

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Unless otherwise specified, registered trademarks are property of SIJ Metal Ravne company. Copyright 2016 by SIJ Metal Ravne d.o.o. All rights reserved. Contact our Sales Office for more information.