SIRAPID 3243 Steel

Brand Name | Ravne | Mat. No. | DIN | EN | AISI/SAE |

SIRAPID 3243 | BRCMO | 1.3243 | S6-5-2-5 † | HS6-5-2-5 | M35 |

Chemical Composition (in weight %)

C | Si | Mn | Cr | Mo | Ni | V | W | Others |

0.91 | max. 0.45 | max. 0.40 | 4.15 | - | 1.90 | 6.30 | - | Co: 4.75 |

Description

M35 is molybdenum high speed steel. Very high resistance to wear and to softening at elevated temperatures. High resistance of cutting edge and good toughness. Deep hardening response. High hot hardness.

Highly stressed drills, milling cutters, profile cutting tools, thread cutting drills and cold forming tools.

Modulus of elasticity [103 x N/mm2]: 217 Density [g/cm3]: 8.1

Thermal conductivity [W/m.K]: 19.0 Electric resistivity [Ohm mm2/m]: 0.60 Specific heat capacity[J/g.K]: 0.46

20-100oC | 20-200oC | 20-300oC | 20-400oC | 20-500oC | 20-600oC | 20-700oC |

9.7 | 10.5 | 11.0 | 11.4 | 11.5 | 12.0 | 12.5 |

Soft Annealing

Heat to 820-880oC, cool slowly in furnace. This will produce a maximum Brinell hardness of 230-300.

Stress relieving to remove machining stresses should be carried out by heating to 650oC, holding for one hour at heat, followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Heat to 450-600oC, preheat to 850oC and then to 1050oC. Harden from a temperature of 1210-1250oC followed by oil, air quenching or warm bath 550oC. Hardness after quenching is 64-66 HRC.

Transformation temperatures: Ac1=824oC , Ac3=853oC.

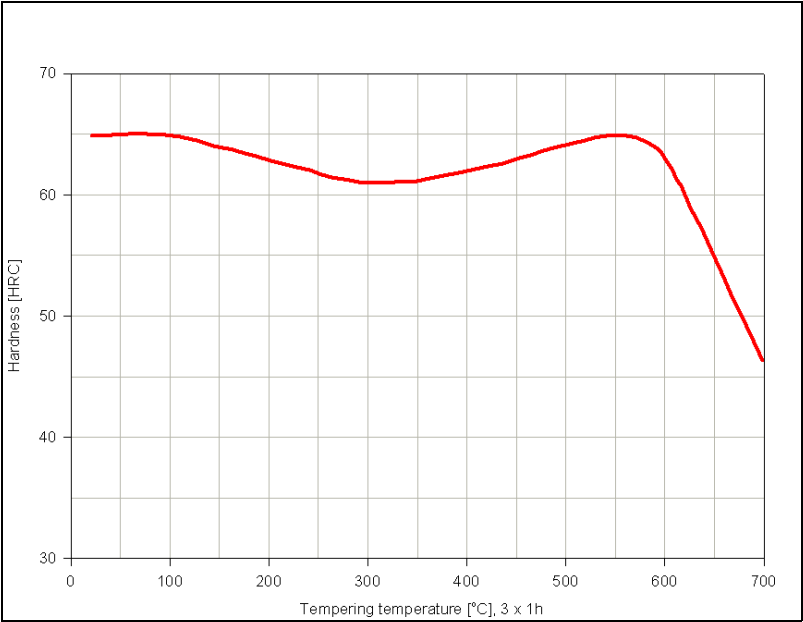

Tempering temperature: 3 x 1 hour at 540-570oC.

200oC | 300oC | 400oC | 500oC | 525oC | 550oC | 575oC | 600oC | 650oC | 700oC |

63 | 61 | 62 | 64 | 64.5 | 65 | 64 | 63 | 55 | 46 |

Tempering Diagram

Forging

Hot forming temperature: 1100-900oC.

No data.

Not normally employed in applications requiring corrosion resistance.

Forms manufactured: Please see the Dimensional Sales Program.

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as the become available.

Unless otherwise specified, registered trademarks are property of SIJ Metal Ravne company. Copyright 2016 by SIJ Metal Ravne d.o.o. All rights reserved. Contact our Sales Office for more information.